BolanmuEnergy as a professional Power Inverter manufacturer, PCB as the main parts of the inverter, PCB quality and performance is very important, so Bolanmu attaches great importance to the production and quality of PCB, choose independent production, firmly control the quality. In Bolanmu’s production workshop there is a production line specializing in the manufacture of PCB.

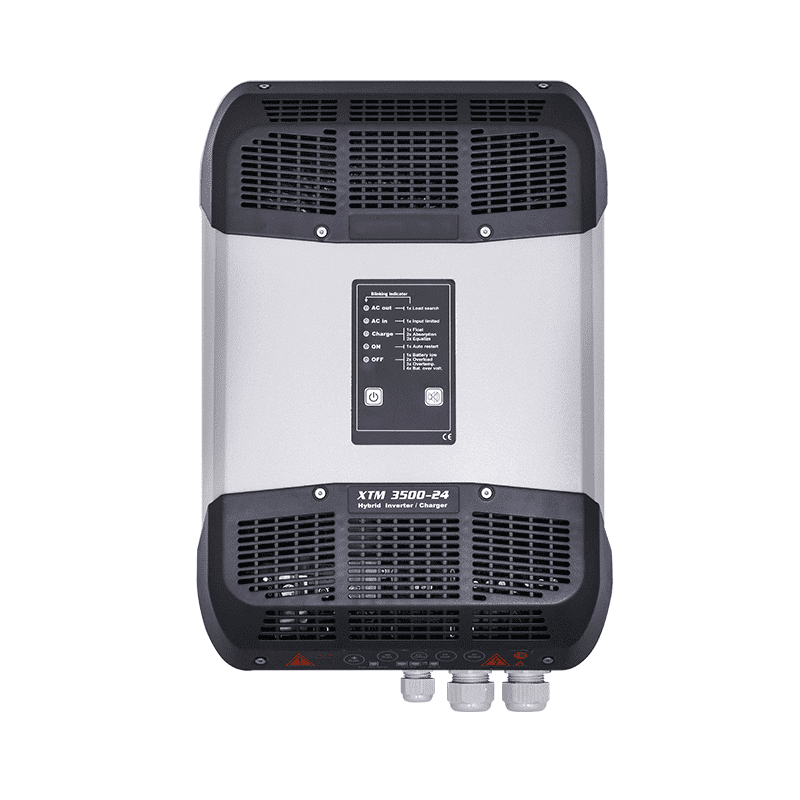

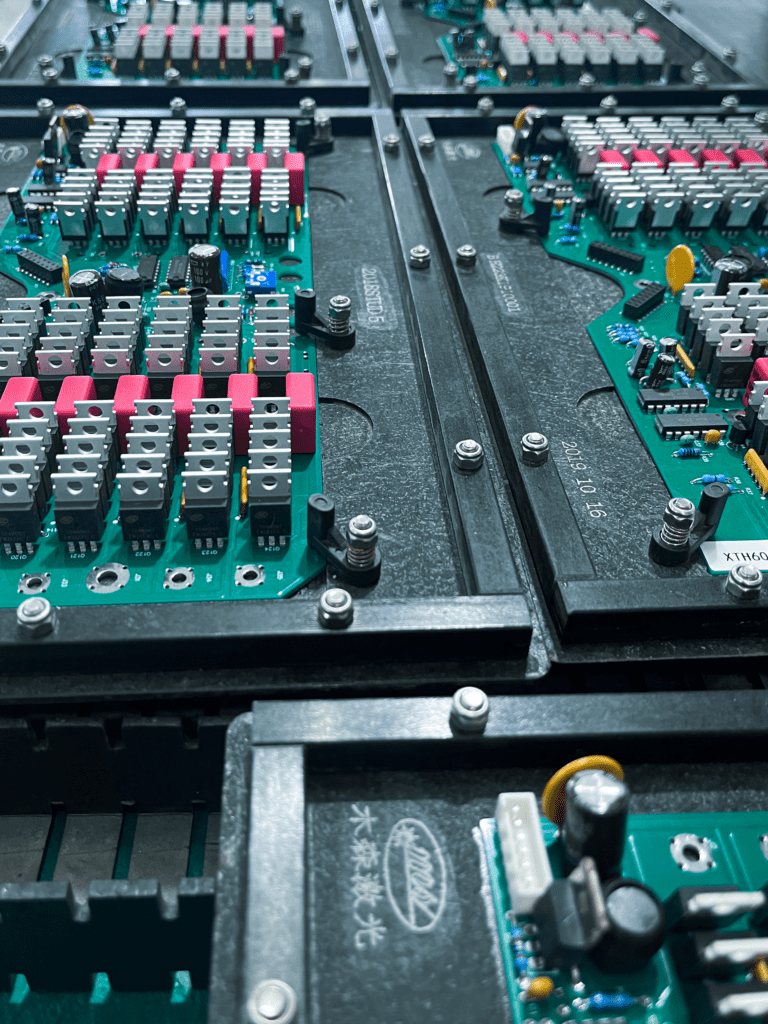

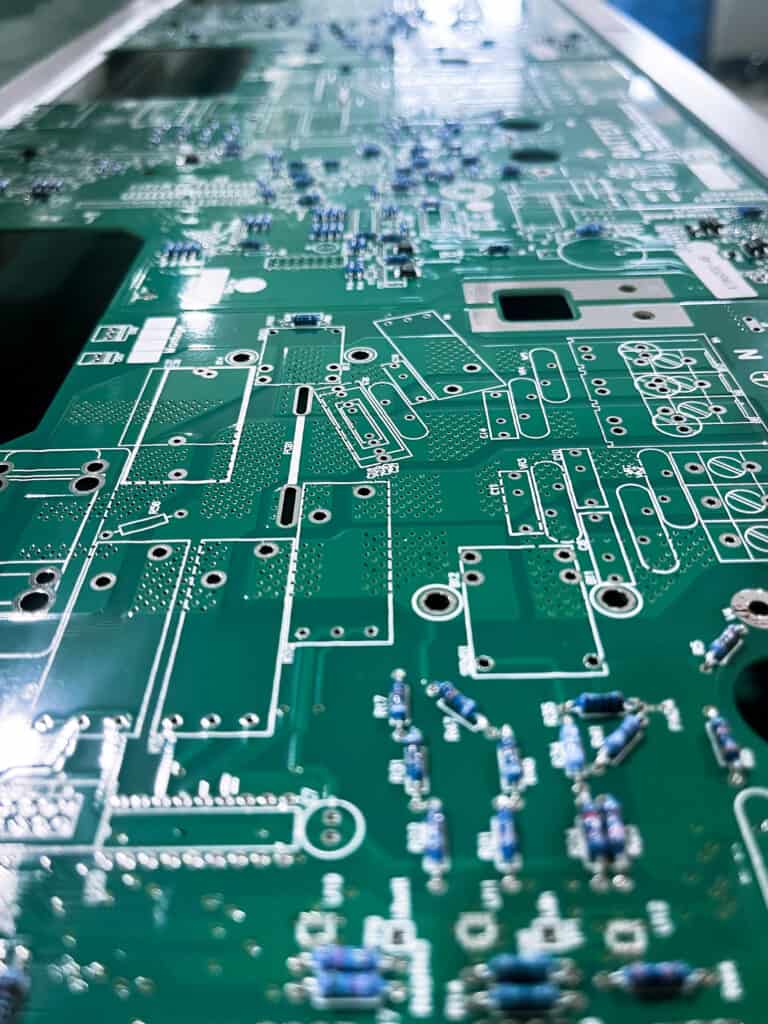

The following three pictures show the PCB of XTH6000-48 being produced by Bolanmu

What is PCB?

Printed Circuit Board (PCB) is a board made of insulating material such as fiberglass, epoxy resin, or other composite materials, with a thin layer of copper on both sides. The copper layer is etched away to form a complex pattern of interconnected circuits that create a pathway for electricity to flow through the board. PCBs are used in electronic devices to connect and control the different components, such as microprocessors, capacitors, resistors, and transistors. PCBs are essential for the functionality of many modern electronic devices, including computers, mobile phones, televisions, and medical equipment. The PCB design is critical for the device’s performance, efficiency, and safety, and any fault or error in the PCB can result in the device not functioning correctly or, worse, causing damage to other components or the user.

The role of PCB in inverter?

A Printed Circuit Board (PCB) is an essential component of an inverter, which is a device that converts DC power into AC power. The PCB in an inverter serves as the backbone for the entire system, connecting and controlling all the electronic components.

The PCB in an inverter is a thin board made of insulating material such as fiberglass, epoxy resin, or other composite materials. The board is coated with a thin layer of copper on both sides, which is then etched away to form a complex pattern of interconnected circuits. These circuits form a pathway for electricity to flow through the board, connecting all the components of the inverter.

The components mounted on the PCB in an inverter include microprocessors, capacitors, resistors, transistors, and diodes. These components work together to control the power flow, voltage, and frequency of the inverter. The microprocessor is the brain of the inverter, which controls the entire operation, including monitoring and regulating the input and output voltage and frequency. The capacitors and resistors are used to filter out any noise or interference that may be present in the input power, ensuring a clean and stable output. The transistors and diodes are responsible for switching the power on and off and for converting the DC power into AC power.

The components mounted on the PCB in an inverter include microprocessors, capacitors, resistors, transistors, and diodes. These components work together to control the power flow, voltage, and frequency of the inverter. The microprocessor is the brain of the inverter, which controls the entire operation, including monitoring and regulating the input and output voltage and frequency. The capacitors and resistors are used to filter out any noise or interference that may be present in the input power, ensuring a clean and stable output. The transistors and diodes are responsible for switching the power on and off and for converting the DC power into AC power.

Why does Bolanmu as the Power Inverter manufacturer want to produce and manufacture PCB itself?

In conclusion, the PCB in an inverter is a critical component that connects and controls all the electronic components of the device. The PCB design ensures efficient power flow and heat dissipation while minimizing interference and crosstalk. The high-quality manufacturing and testing of the PCB are crucial for the inverter’s functionality, reliability, and safety. Without the PCB, the inverter would not be able to function, and the many benefits of using inverters for power conversion would not be possible.The PCB in an inverter must be manufactured to high standards of quality and reliability.